Wire Mesh in UAE

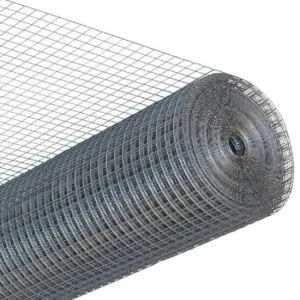

(12 products available)Wire mesh is also known as a wire fabric or wire cloth with countless and varied uses, wire cloth is a product that is widely utilized and versatile. An endless number of specifications can be made for a wire mesh, depending on the needs and utilities.It describes two or three-dimensional lattices composed of two or more metallic wires connected to one another using various techniques as knitting, weaving, welding, or netting. Its main objective is to fulfill the needs of applications that call for filtering devices.It is observed that this specification is utilized in common appliances like strainers, window nets, animal fences, mosquito nets, etc.Industrial supplies encompass wire mesh, essential for filtration, fencing, and structural support across diverse industrial applications worldwide.

Wire mesh is also known as a wire fabric or wire cloth with countless and varied uses, wire cloth is a product that is widely utilized and versatile. An endless number of specifications can be made for a wire mesh, depending on the needs and utilities.It describes two or three-dimensional lattices composed of two or more metallic wires connected to one another using various techniques as knitting, weaving, welding, or netting. Its main objective is to fulfill the needs of applications that call for filtering devices.It is observed that this specification is utilized in common appliances like strainers, window nets, animal fences, mosquito nets, etc.Industrial supplies encompass wire mesh, essential for filtration, fencing, and structural support across diverse industrial applications worldwide.

On TradersFind, our B2B portal, you can easily get in contact with the best wire mesh suppliers & manufacturers in UAE from leading companies. You can find the leading wire mesh companies or wire mesh exporters providing wire mesh in UAE.Our comprehensive listings and detailed product specifications make it seamless to find the right wire mesh in UAE to fulfill your requirements.Wire mesh is also known as a wire fabric or wire cloth with countless and varied uses, wire cloth is a product that is widely utilized and versatile. An endless number of specifications can be made for a wire mesh, depending on the needs and utilities.It describes two or three-dimensional lattices composed of two or more metallic wires connected to one another using various techniques as knitting, weaving, welding, or netting. Its main objective is to fulfill the needs of applications that call for filtering devices.It is observed that this specification is utilized in common appliances like strainers, window nets, animal fences, mosquito nets, etc.Industrial supplies encompass wire mesh, essential for filtration, fencing, and structural support across diverse industrial applications worldwide.

On TradersFind, our B2B portal, you can easily get in contact with the best wire mesh suppliers & manufacturers in UAE from leading companies. You can find the leading wire mesh companies or wire mesh exporters providing wire mesh in UAE.Our comprehensive listings and detailed product specifications make it seamless to find the right wire mesh in UAE to fulfill your requirements. View less

- Material : Steel

- Strength : High

View more...

Quality Wire Products

Other Categories

- Material : Stainless Steel

- Wire Diameter : Diverse

View more...

Stainless Inox International FZCO

Other Categories

- Material : Steel

- Mesh Size : Varied

View more...

BRC Arabia LLC

Other Categories

- Panel Size: Customizable :

- Strength: High :

View more...

Al Gurg Building Services

Other Categories

- Material : Stainless Steel

- Mesh Size : Varied

View more...

Fanatech Engineering And Trading LLC

Other Categories

- Tensile Strength : Strong

- Wire Gauge : Flexible

View more...

SRK Metals FZE

Other Categories

- Material : Steel

- Strength : High

View more...

Emirates Rebar Limited

- Material : Steel

- Mesh Size : Varied

View more...

Other Categories

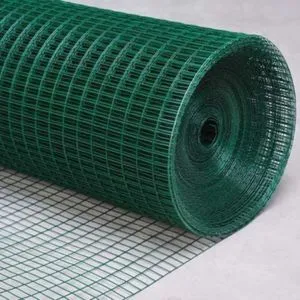

- Material : PVC Coated Steel

- Coating : Resilient PVC

View more...

Dragon Mart

Other Categories

- Roll Length : 15Mtr or 30Mtr

- Roll Width : 1.5Ft(45cm), 6Ft (180cm)

View more...

Excel Trading Company LLC

Other Categories

An easy way to post your sourcing requests and get quotes.

- One request, multiple quotes

- Verified suppliers matching

- Quotes comparison and sample request

Types of Wire mesh

The various types of wire mesh in Dubai are categorized based on their characteristics, weave patterns, methods of manufacture, and uses. Each of the several varieties is made to satisfy the specifications for weight, finish, and strength in a project or application. Three elements will determine the type of wire mesh that will be used: finish, metal type, and pattern type. The two most important factors are finish and metal.

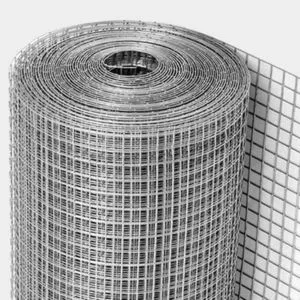

1.Galvanized Welded Wire Mesh:

Galvanized welded wire mesh is composed of plain or carbon steel wire which is galvanized,a process that involves applying a zinc coating.The zinc layer serves as a shield that protects the wire mesh from rust and corrosion.It is welded using galvanized wire or plain steel wire that is galvanized.It is perfect for infill panels, window guards, architecture, building and construction, agriculture, gardening, and fence.

2.Stainless steel wire mesh:

Stainless steel wire mesh offers superior protection and performance while possessing all the advantageous qualities of stainless steel. Steel is frequently used to make wire mesh, but air exposure causes it to corrode quickly. With the addition of chromium, which prevents oxidation and makes stainless steel resistant to rust, stainless steel retains the same chemical composition as regular steel.In wire mesh manufacturing, stainless steel is known for its dependability, reliability, and durability. Stainless steel is suitable for any outdoor application due to its resistance to rust. It is the most widely used type of wire mesh because it continuously provides durability and strength.

3.PVC Coated Wire Mesh:

PVC Coated Wire Mesh is a marine grade polyvinyl chloride (PVC) coating applied on welded and galvanized steel fabric. It is fuse bonded to the wire for the highest level of protection.PVC coating is solid, corrosion-resistant, reasonably priced, and has good insulating qualities.It is one of the decorative wire mesh.Applications for PVC mesh include architectural fencing, machine guarding, and freshwater and saltwater traps.

Wire mesh patterns

The wire mesh pattern determines its capacity and how it can be used. There are countless types of weave patterns, both basic and tailored to meet a particular need. The presence or absence of crimping, which mechanically modifies the shape of the weft or warp wires, is one factor that separates the different designs.

1.Crimped wire mesh:

Crimped wire mesh is a square or rectangular weave that is woven using a crimping mesh machine.The procedures that are utilized to create crimped wire mesh involves compressing the wire so that the warp and weft wires overlap each other.

2.Non-crimped wire mesh:

Non-crimped wire is just plain wire mesh made by weaving the warp and weft wires in a straightforward over-under pattern. The finished product features a smooth, flat surface and a straightforward appearance. Plain or non-crimped wire has historically had a larger mesh count.

3.Double weave wire mesh:

Double weave wire mesh is a variation of the pre-crimped weave pattern. In the weaving process, the warp wires pass over and under two weft wires to form a wire mesh pattern capable of withstanding stressful and demanding uses. The double weave wire mesh pattern creates a wire mesh that is exceptionally durable, making it suitable for fencing, barbeque pit screens, and vibrating screens in mining operations and crushers.

4.Stranded weave wire mesh:

Stranded weave wire mesh uses small-diameter weft and warp wire bunches that are woven in a plain square pattern. The use of multiple wires creates a twill style pattern that is extremely tight and strong. The tightness and density of the weave are useful in microfiltration cloth.

5.Flat top weave wire mesh:

The flat top weave produces a strong, locking wire mesh with a flat surface by using crimped weft wires and non-crimped warp wires. Since there are no wires that protrude from the top of the mesh to wear it, it has a long abrasive life. Because of its low flow resistance, flat top weave wire mesh is frequently used in structural and architectural applications where a smooth surface is required. Vibrating screens are a typical use for flat top weaves.

Wire Used to Make Wire Mesh

Wire mesh is mainly composed of wire, which is derived from various ferrous and non-ferrous metals. There are different gauges (numbers that indicate a wire's thickness) for the wire that is used to make wire mesh. Lower numbers in the gauge numbering system indicate thicker wires, whereas higher numbers indicate thinner wires.

The following are the wires that are used to make wire mesh:

1.Carbon Steel in wire mesh:

Carbon steel is one of the most popular metal wires used to manufacture wire mesh.It is a cheap, multipurpose metal that is mostly iron with a tiny bit of carbon. It is used to make window guards, screens, and mining separation screens. Carbon steel wire mesh can be powder coated with plastic or coated with zinc to create galvanized steel mesh.

2.Stainless Steel in Wire Mesh:

Stainless steel wire mesh is a popular choice for architectural applications because of its remarkable strength, durability, and glossy sheen. A wide variety are utilized in the production of stainless wire mesh.

3.Aluminium wire in wire mesh:

Aluminum is cheap, lightweight, malleable, flexible, and resistant to corrosion. Among the non-ferrous metals used to make wire mesh, it is the most widely used. To improve some of its other qualities and make it stronger, most aluminum is alloyed with other metals in specific amounts, such as copper, magnesium, zinc, or silicon.

4.Copper in wire mesh:

Copper wire mesh has outstanding electrical and thermal conductivity and is ductile and flexible. It is frequently utilized in electrical applications and as radio frequency interference shields. Similar to aluminum, copper is typically alloyed to improve and enhance its inherent qualities rather than being used in its pure state.Copper changes its color when exposed to salt,moisture and sunlight.To prevent the change in color of copper wire mesh,it is treated with coating with chemicals,which slow downs the oxidation process.

5.Brass in wire mesh:

Brass is an alloy of copper and zinc. It is a soft, pliable metal known as yellow brass or high brass in wire mesh manufacturing.Brass wire mesh has a higher zinc concentration, which results in hardened mesh with excellent tensile strength and abrasion resistance.The yellow tone of industrial grade brass wire mesh makes it a popular choice for artistic decorative additions to architectural projects.

6.Barbed wire in wire mesh:

Barbed wire is a type of fencing wire constructed with sharp edges or points arranged at intervals along the strand. Barbed wire mesh is used to construct inexpensive fences and is used atop walls surrounding secured property.

Find the best wire mesh suppliers & manufacturers in UAE on TradersFind

TradersFind is a reliable platform for those who are looking for wire mesh in UAE.You can find different verified wire mesh manufacturers in UAE from the category page you can get the complete details such as contact details,location or whatsapp number.Through that, you can get in touch with them and get your requirements fulfilled.Wire mesh importer connects with global markets by distributing high-quality wire mesh products for various industrial applications.In short, if you are looking for a wire mesh exporter in Sharjah or in any other emirate,TradersFind is a right platform for you to connect with the top wire mesh companies without any difficulty.

FAQs:

Q1: What are the features of a wire mesh?

A1: It has a strong resistance to acids and alkalis, corrosion High durability, toughness, high tensile strength, and resistance to wear.Wire mesh is mainly used in industrial applications when separation or filtration is needed.It is also popular for use in commercial applications, like insect screening or animal fencing.

Q2: What is the lifespan of wire mesh?

A2: Galvanized wire mesh is made to withstand corrosion and rust even in damp conditions. Galvanized wire mesh can last anywhere from 20 to 50 years in high-humidity, high-moisture environments. This depends on the wire's thickness and the quality of the galvanization.

Q3: Is wire mesh flammable?

A3: Wire mesh is known as an effective fire-resistant structural material because of its excellent flame quenching performance.

Q4:What is the difference between wire mesh and fiber mesh?

A4: In flooring applications, fiber and wire mesh can frequently be used interchangeably. Compared to wire mesh, which is typically used for heavier concrete forms, fiber mesh is more suited for delicate concrete forms and thin concrete layers.

Q5: What is the alternative to wire mesh?

A5: Fiber concrete reinforcement can be an alternative to wire mesh.It can be a cost-effective, durable and even sustainable alternative to conventional steel like wire mesh.Copyright © 2024 Interconnect Marketing Management L.L.C All rights reserved.