Lifting Equipments in UAE

(12 products available)Lifting Equipments, also known as lifting gear, is any device that is used to lift or lower loads in various industries and applications. These machines range from simple hand-operated tools to complex motorized systems, all designed to reduce manual labor and minimize workplace injuries. Common types include cranes, hoists, forklifts, and elevators, each serving specific purposes in the construction, manufacturing, warehousing, and logistics sectors. Lifting equipments enhances productivity by allowing workers to handle materials that would otherwise be impossible to move manually. Safety features such as load limiters, emergency stop buttons, and overload protection systems ensure the well-being of operators and nearby personnel. Regular maintenance and inspections are essential to keep this equipment in optimal working condition and comply with safety regulations. As technology advances, modern lifting equipment incorporates features like remote control operation, automated positioning systems, and real-time load monitoring. These innovations further improve efficiency, precision, and safety in material handling operations across diverse industrial settings. If you are looking for lifting Equipments in UAE. TradersFind connects you with leading Lifting Equipments manufacturers in UAE that provide a wide range of lifting equipments for your business. Our complete listings and detailed product specifications make it seamless to find the best Equipments across UAE to fulfill your requirements.

Lifting Equipments, also known as lifting gear, is any device that is used to lift or lower loads in various industries and applications. These machines range from simple hand-operated tools to complex motorized systems, all designed to reduce manual labor and minimize workplace injuries. Common types include cranes, hoists, forklifts, and elevators, each serving specific purposes in the construction, manufacturing, warehousing, and logistics sectors.

Lifting equipments enhances productivity by allowing workers to handle materials that would otherwise be impossible to move manually. Safety features such as load limiters, emergency stop buttons, and overload protection systems ensure the well-being of operators and nearby personnel. Regular maintenance and inspections are essential to keep this equipment in optimal working condition and comply with safety regulations. As technology advances, modern lifting equipment incorporates features like remote control operation, automated positioning systems, and real-time load monitoring. These innovations further improve efficiency, precision, and safety in material handling operations across diverse industrial settings.

If you are looking for lifting Equipments in UAE. TradersFind connects you with leading Lifting Equipments manufacturers in UAE that provide a wide range of lifting equipments for your business. Our complete listings and detailed product specifications make it seamless to find the best Equipments across UAE to fulfill your requirements.

Lifting Equipments, also known as lifting gear, is any device that is used to lift or lower loads in various industries and applications. These machines range from simple hand-operated tools to complex motorized systems, all designed to reduce manual labor and minimize workplace injuries. Common types include cranes, hoists, forklifts, and elevators, each serving specific purposes in the construction, manufacturing, warehousing, and logistics sectors.

Lifting equipments enhances productivity by allowing workers to handle materials that would otherwise be impossible to move manually. Safety features such as load limiters, emergency stop buttons, and overload protection systems ensure the well-being of operators and nearby personnel. Regular maintenance and inspections are essential to keep this equipment in optimal working condition and comply with safety regulations. As technology advances, modern lifting equipment incorporates features like remote control operation, automated positioning systems, and real-time load monitoring. These innovations further improve efficiency, precision, and safety in material handling operations across diverse industrial settings.

If you are looking for lifting Equipments in UAE. TradersFind connects you with leading Lifting Equipments manufacturers in UAE that provide a wide range of lifting equipments for your business. Our complete listings and detailed product specifications make it seamless to find the best Equipments across UAE to fulfill your requirements.

- Load Capacity : Heavy Load Capacity

- Material : Steel

View more...

Manarat Al Falah Trading LLC

- Material : Heavy Duty Steel

- Load Capacity : 500 kg To 1000 kg

View more...

Alfa Lift

- Jaw Width : 51mm

- Pin Diameter : 35mm

View more...

Advance Oil Field Supplies

Other Categories

- Material : Forged Carbon Steel

- Body Finish : Hot dip galvanized

View more...

Dutest Industrial LLC

- Material : Heavy Duty Steel

- Application : Industrial Use

View more...

Zaker Trading LLC

- Load Capacity : 200 kg

- Power Source : Electric

View more...

Arabian Access Equipment Rental

- Capacity : 5ton

- Running Test Load : 7.5T

View more...

Lokhandwala Trading LLC

- Material : Steel

- Load Capacity : High

View more...

Saasa Equipment LLC

- Color : Green

- Material : Alloy Steel

View more...

Shabbir Enterprises LLC

Other Categories

- Load Capacity : 750 kg

- Power Rating : 0.06KW

View more...

Xplatform Cradles And BMU

An easy way to post your sourcing requests and get quotes.

- One request, multiple quotes

- Verified suppliers matching

- Quotes comparison and sample request

Lifting Equipments in UAE

Lifting Equipments UAE is used for heavy-duty tasks in the shipping, warehousing, oil, and gas, and construction industries all need the use of lifting Equipments. This comprises devices that help lift and transport big objects securely and effectively, such as cranes, hoists, forklifts, and slings. Lifting equipments is necessary because of UAE's expanding port and industrial operations, as well as the country's developing building industry. All equipments is guaranteed to be safe, examined, and maintained regularly by local rules. Lifting Equipment is becoming smarter and more efficient across a range of industries thanks to advanced technologies, such as automation and remote control.

Types of Lifting Equipments in UAE

Large, heavy materials must be lifted and moved carefully, efficiently, and safely, whether they are being moved inside production and warehouse facilities or outside. Enhancing performance and productivity requires the appropriate automation features and the best lifting Equipments.

Cranes

Heavy materials can be moved horizontally and raised and lowered with the help of cranes. They are frequently employed in the production of heavy machinery and the construction sector. The most popular varieties are rough terrain cranes, engine cranes, jib cranes, and mobile gantry cranes. Cranes lift objects with a variety of tools, such as sheaves, chains, wire ropes, and hoist ropes. Crane operations require a high-quality heavy lifting Equipments level of safety, and operators need to be properly trained.

Forklifts

For lifting and moving things, forklifts are powered industrial trucks with prongs up front. They lift and lower the forks using hydraulic systems. To position and transfer materials, the operator can regulate the forklift's movement and direction. Pallets of goods, crates, and other large, heavy objects are frequently lifted by forklifts. Usually, an expert operates a forklift. Diesel, gasoline, and propane are the powers used in a forklift. A forklift is designed to be handled safely and without causing the driver any technical difficulties. There are many different kinds of forklift equipment available. A weight of up to 50 tons can be supported using forklift equipment.

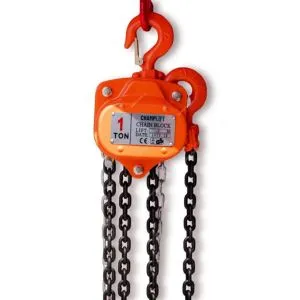

Hoists

Hoists are essential to productivity at work. Lifting systems with chain hoists are frequently seen in warehouses and industrial lifting Equipments workshops. Since they are often small, they can readily handle large objects or objects with odd shapes that are difficult to lift by hand. Another widely used device is wire rope hoists, which are often made for heavier and more frequent loads.

Pneumatic, electric lifting Equipments, or manual hoists are available. To raise objects, they employ sturdy hooks and chains or wire ropes. The crane can be fastened to overhead cranes, monorails, or stationary ceiling points.

Winches

A rope or wire rope's tension can be changed by pulling in, letting out, or adjusting the winch. They are frequently employed in applications involving weight lifting, anchoring, and towing. Winches can be driven by internal combustion engines, electric lifting Equipments, hydraulic, or pneumatic drives in addition to being manually operated. They are made up of a hand crank and a spool, and they can be used to wind a rope or cable in or out to move a load that is tied to it.

Jacks

Jacks are tools for exerting strong forces or lifting large objects. They employ mechanical lifting Equipments advantage to raise a building so that the foundation may be replaced or to elevate a car off the ground for tire changes. There are numerous varieties and sizes of jacks, each intended for a particular use. House jacks, hydraulic jacks, and car jacks are a few of the most popular varieties.

Lifting Clamps

By applying inward pressure, lifting clamps are multipurpose pieces of lifting Equipments that are used to hold or fasten things closely together to prevent movement or separation. Clamps are frequently employed in lifting Equipments rental in UAE and provide several applications to manage things including pipelines, steel plates, and concrete slabs. There are several varieties available, such as pipe clamps, plate clamps, and beam clamps, each intended for a particular kind of load.

While plate clamps are made to raise and move steel plates vertically, beam clamps create a lifting point on a beam or girder. Contrarily, pipe clamps are employed to lift, move, and position pipes or round bars.

Vacuum Lifters

Vacuum lifters use suction cups to grasp and raise items, usually in the shape of sheets or panels. The material is lifted and moved using a vacuum pump after the vacuum lifter seals off the area between the suction cups and the material surface. Sheet metal, glass panels, and other flat items are all liftable by them.

Hydraulic Lift Tables

A hydraulic cylinder is used to raise or lower hydraulic lifting Equipments UAE. The table is raised and lowered by cylinders that stretch and retract. They are frequently employed to arrange goods or Equipments ergonomically. Pallets, materials, and heavy-duty lifting Equipments can all be raised with hydraulic in manufacturing environments.

Key Industries Using Lifting Equipments in UAE

Lifting devices and Equipments are necessary for a wide range of businesses for a variety of reasons. Many occupations require the ability to move big objects, create structures, or even handle exotic, wild animals.

It can be challenging to know where to begin and which Equipments is necessary for your scenario because there are so many different sorts and kinds of Equipments available.

Engineering

Engineers build tools, devices, and vehicles for a variety of applications, bridging the gap between science and industry. In addition to designing and building things, engineers are skilled with a wide range of tools, including wrenches and hoists.

An engineer may need to elevate items to work underneath them or suspend components to examine and make necessary adjustments, depending on the project they are working on. Depending on its size, an object could be suspended using a chain block or, for certain engineers, an electric hoist. This kind of lifting Equipments goes hand in hand with lifting slings and shackles.

Agriculture

Working with huge, heavy materials is necessary for a large portion of the agricultural economy, from planting crops and handling grain to bulk-feeding animals and harvesting crops at different times of the year. For this reason, farms need a lot of machinery to harvest and carry items, such as tractors, forklifts, and combine harvesters.

Forklift trucks, telescopic handlers, wire rope hoists, cable pullers, winches, slings, and several other lifting and moving tools are all very helpful when working in agriculture.

Zoos

Zoos need to utilize a lot of lifting Equipments while caring for huge animals to protect the safety of the zookeepers and the animals themselves. Unlike the little, domestic animals we are used to, working with large, wild animals can be surprising at times due to their sheer size and difficulty handling.

For example, when an animal at the zoo requires surgery, it must be raised; a hoist and specialized harness are frequently used for this purpose. Along with lifting instruments and Equipments, a specific lifting table is also needed. The animal is raised to the proper height on this huge stainless steel table, enabling veterinarians to provide care. You can get a sense of the strength of this Equipments by considering that a male lion weighs roughly 190 kg.

Film Sets

The film business must build sets, move massive items, handle explosives, and flip automobiles during fast-moving chase scenes. This means that to put, move, and suspend enormous objects with control and precision, people who work on movie sets need sturdy lifting Equipments rental companies in UAE.

As well as stunts, behind the scenes plenty of Equipments is needed from tripods to jibs and cranes, so they can move the camera smoothly and obtain the right shot. With all of this Equipments, the film industry can now effortlessly create visually gorgeous films that have a seamless appearance.

Building and Constructions

Building construction and skyscraper construction involve a great deal of heavy lifting and the expertise of professionals to use this Equipments correctly. Reliable Equipments is crucial, whether you need to raise one of your workers to a higher level before the stairs are installed or scaffolding needs to be built.

Particularly useful for construction sites would be a scaffold runway system or scaffold hoist, which are excellent for moving loads up scaffolding. Builders and construction lifting Equipments workers undoubtedly use electric or manual hoists regularly. Impressively, some hoists are capable of supporting 50,000 kg.

Factors to Consider When Choosing Lifting Equipments in UAE

It is important to determine what lifting Equipments dealers UAE best meet your needs before starting any lifting-related task. Selecting the appropriate hoisting apparatus is crucial for guaranteeing security and effectiveness across many sectors and uses.

Load Capacity

Determine the maximum weight the Equipments needs to lift. A little over your maximum requirement should be handled by the Equipments you have chosen to account for any unanticipated growth. The size, overall weight, surface features, consistency (or lack thereof) of shape, material, construction, and fragility of the object being lifted are all important details that crane and hoist makers need to know. Moreover, as the load is handled, determine whether it will be dry, damp, dusty, oily, or in another condition. It's also critical to determine whether the crane and hoist are required to carry multiple types of loads.

Lift Height

Consider the height at which the machinery must raise the weight. Choose a piece of Equipments that can lift a certain height without going beyond safe operating restrictions as different types have different lift height capacities. It is crucial to make sure that lifting Equipments can safely and effectively reach the necessary height when determining the lift height. Make sure your Equipments can support the load while reaching height because increasing light height can also have an impact on the load's stability.

Environment

Evaluate the space where the Equipments will be utilized. For instance, diesel forklifts are more suited for outside use because of their durability, but electric hoists are best used indoors. Additionally, you must consider the available area; if it is limited, you must make sure the Equipments and maneuverability are adequate. Lifting equipments suppliers can provide guidance on choosing the right equipment for specific environments.

Frequency of use

Determine the frequency at which the equipment will be operated. Purchasing sturdy, long-lasting equipment is essential to guaranteeing its lifespan and dependability when it is used frequently. Lifting equipments companies often categorize usage into different classes:

• Class A: Spoken or Partial Support. These are frequently the kinds of applications where careful handling of the machinery at moderate speeds and lengthy idle times in between lifts takes place.

• Class B. Light Service. Applications for light use and low speed, with loads ranging from zero to the full rated capacity, two to five lifts per hour, on average, at a height of ten feet per lift.

• Class C: Service in Moderation. At five to ten lifts per hour at an average height of fifteen feet, loads average fifty percent of the specified capacity.

• Class D. Heavy Service. Loads that are between fifty and sixty-five percent and more of the specified capacity are handled continuously at fast rates, averaging fifteen feet each lift in an hour.

• Class E. Severe Service. Nearly constant operation, frequently in challenging conditions, with 20 or more lifts per hour at 100% or close to that capacity.

• Class F. Continuous Severe Service. continuous use at over 100% of the rated capacity in difficult circumstances. These cranes could have been specially made for extreme dependability during crucial tasks.

Mobility

Take into account whether or not the equipment must be movable. While stationary equipment, such as overhead cranes, offers stability for repetitive activities, movable equipment, such as forklifts and mobile cranes, offers flexibility. Lifting equipments suppliers in UAE typically offer a range of both stationary and mobile options.

Safety Features

To avoid mishaps and injuries, make sure these equipments have the necessary safety features, such as overload protection, emergency stop capabilities, and enough guarding. The most crucial consideration when choosing lifting equipments is safety features. It is vitally important to guarantee user and workplace safety. Equipments with safety features including overload protection systems, emergency stop controls, and load-limiting devices should be identified. These elements lower the chance of an accident or injury and improve safety on the job site. Lifting equipments companies in UAE prioritize safety in their product offerings and can guide on selecting equipment with appropriate safety features for specific applications.

The Budget

While it may be tempting to choose the crane and hoist combo that is the least expensive among all the available choices, there's a good risk that the system won't be designed to satisfy the needs of the application as it stands. Though it probably won't be the cheapest, a well-engineered system has a greater chance of lasting longer, having fewer problems, less downtime, and a higher level of safety. Reputable lifting equipments manufacturers understand that all capital Equipments investments include additional expenditures beyond the initial purchase price. When adding up the Equipments expenses, don't forget to include installation, replacement components, maintenance contracts, service agreements, and the desired level of field service team responsiveness to problems.

Innovations and Trends in Lifting Equipments

Crane operations have been revolutionized by extraordinary technological breakthroughs in the construction and heavy-lifting industries. Automation is now a major trend that is raising production, safety, and efficiency to unprecedented levels. Crane warning systems, which give operators real-time data and alarms to prevent accidents and guarantee smooth operations, are essential to these improvements.

The rise of automation

Utilizing modern technologies to complete jobs with the least amount of human intervention is known as automation in crane operations. The requirement for greater accuracy, safety, and efficiency in building projects is what's causing this change. Automated cranes are capable of performing intricate operations with great accuracy, including weight lifting, positioning, and maneuvering. Sensors, software, and control systems are essential elements of automation in cranes that combine to optimize operations.

Integration of IoT and Big Data

Crane technology is being transformed by big data analytics and the Internet of Things (IoT). Cranes that are Internet of Things (IoT) enabled have sensors that gather and send data instantly. Crane load indicators, crane wind speed, and other crucial characteristics are covered in this data. Operators can foresee possible problems, make well-informed decisions, and maximize crane performance by studying this data. Predictive maintenance is another benefit of IoT integration that lowers downtime and increases Equipments longevity.

Advanced Crane Warning Systems

Crane warning systems of today represent the cutting edge of safety technology. Real-time alerts and warnings regarding possible hazards, such as exceeding load capacity or unfavorable weather conditions, are given to operators by these systems. Crane warning systems can use anemometers to track wind speed, identify two-block situations, and make sure the crane is operating within safe bounds. Construction sites can greatly lower their accident risk and improve overall safety by implementing these technologies.

Teleoperation and Remote Control

In crane operations, remote control and teleoperation technologies are growing in popularity. With the use of these technologies, crane operators may safely operate the machines from a distance, reducing their exposure to dangerous situations. Cranes that are operated remotely can be precisely managed, even in difficult situations, guaranteeing efficiency and safety.

Automation and the integration of innovative technologies are the keys to the future of crane technology. The Internet of Things, remote control technology, and crane warning systems are all contributing to notable gains in production, efficiency, and safety. The construction and heavy lifting sectors stand to gain from improved performance and lower hazards as these technologies develop further. Crane operations may stay at the forefront of innovation and safety by adopting these trends.

Maintenance and Lifecycle Management of Lifting Equipments

The efficient operation of a warehouse depends on the proper management of its equipment. Every piece of equipment, from conveyors to forklifts, is essential to increasing efficiency and output. Maintenance is one of the most important aspects of equipment management. Good maintenance procedures guarantee that machinery stays in top shape, minimizing downtime and lowering total expenses.

For lifting equipments to last a long time and operate safely, regular maintenance is essential. Observe the manufacturer's recommendations for regular maintenance, repairs, and part replacement. Furthermore, confirm that your equipment conforms with regional laws and guidelines, such as UAE Lifting Operations and Lifting Equipments Regulations (LOLER). Following these rules helps prevent legal problems and possible fines in addition to ensuring safety.

Maintaining your lifting equipment regularly is essential to preventing issues. In general, the three jobs to have in mind when we talk about lifting equipment maintenance are:

• Checks regularly: Planned checks assist in spotting possible problems and enable prompt remedies.

• Maintenance: By keeping parts properly lubricated and cleaned, you may prolong the life of your equipments by preventing wear and tear.

• Repair and replacement of parts: Timely repair or replacement of damaged parts averts more harm and possible mishaps.

Conclusion

TradersFind is a reliable platform for those who are looking for lifting Equipments in UAE. You can find different verified lifting equipments suppliers in UAE. You can get the complete details such as contact details, location, or WhatsApp number. Through that, you can get in touch with top Lifting Equipments Companies in UAE providing high-quality equipment meeting your requirements. In short, TradersFind is the right platform for you to connect with manufacturers across UAE without any difficulty.

Frequently Asked Questions (FAQs)

Q1: What is the purpose of lighting Equipments?

A1: You can use your creativity to try out various lighting approaches to get the desired look when you use professional lighting Equipments. You can add a gentle glow, make strong shadows, or draw attention to particular aspects of the picture.

Q2: What are the considerations of lighting?

A2: The light design process is always started with an understanding of the desired outcome. For instance, the amount of glare and illumination needed, the mood of the area, the objects to be emphasized, the interplay of daylight, the objects to be hidden, and the direction of the light.

Q3: What type of lighting is recommended?

A3: The goal of general or ambient lighting is to completely illuminate a space. It functions independently of other lighting sources to offer a consistent level of illumination across the room. It also serves to provide an overview of the space and guarantee easy and safe traffic flow.

Q4: What is the most common lighting fixture?

A4: Cove, soffit, and valance lighting are the three most popular types of architectural lighting; each is incorporated into the design of the space. Cove lighting bounces light toward the ceiling or upper wall from a ledge, shelf, or recess high quality lifting Equipments on a wall.

Q5: What are the general principles of lighting?

A5: The way that almost all lighting systems work is either by using an electrical current to heat an element till it glows, or to excite gasses so they release light energy. One illustration of the first technique, known as incandescence, is an incandescent light source.

Copyright © 2024 Interconnect Marketing Management L.L.C All rights reserved.