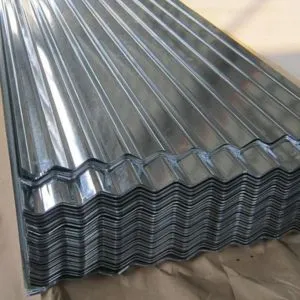

Corrugated sheet in UAE

Corrugated sheet is highly used in the construction and agriculture industries in the UAE. Their light, strength, and durability can resist harsh weather conditions. They come in metals, plastics, and fiberboard materials, making them popular for roofing, cladding, and temporary structures.

The rapid growth of urbanization and industrial activities in UAE is also significantly increasing demand for corrugated sheets in sectors such as warehouse construction, agricultural greenhouses, and protective barriers. Their recyclability and cost-effectiveness also resonate with the sustainability initiatives of UAE. The market will further thrive as companies are looking for energy-efficient, weather-resistant, and versatile building products.

Corrugated sheet market overview in UAE

The corrugated sheets market in UAE has seen consistent growth due to the rising need for long-lasting, affordable, and flexible roofing options in different construction projects. Corrugated roofing sheets are a common option for homes, businesses, and factories due to their various advantages such as durability against the elements, ability to maintain temperature, and simple installation process.

UAE Corrugated Sheet Market Analysis

The demand for the corrugated roof sheets market is increasing because of the country's expanding e-commerce sector, a rise in consumer concern for the environment, and a need for sustainable packaging choices.

Key Highlights

- • Increasing need for these sheets in emerging areas because of their cost-effectiveness and easy accessibility.

- • Growing use of corrugated sheeting in agriculture for livestock shelters, storage spaces, and greenhouses.

- • Increasing demand for corrugated sheet solutions made from metal, such as galvanized steel and aluminium corrugated sheets, because of their long-lasting quality and minimal upkeep.

- • Progress in material science and manufacturing methods has resulted in the creation of corrugated roofing products that are not only more efficient but also more visually appealing.

Market Drivers

The increasing need for affordable and long-lasting sheet roofing options, especially in developing areas and the agricultural industry, is the main factor propelling the corrugated sheets industry.

These sheets are favored for their affordable price and easy accessibility. The simplicity of installing these sheets and their durability against tough weather conditions like heavy rain, strong winds, and extreme temperatures have made them a popular choice for construction projects in both residential and commercial areas in these regions.

Market Segment Analysis

Growing Construction Market

Construction sectors in UAE, including large-scale projects like Expo 2020, smart cities, and infrastructural works, have largely increased demand for corrugated roof sheeting. Corrugated sheets can offer excellent durability with adequate thermal insulation and cost-effectiveness under the segments of roofing, cladding, and structural features, both in the residential and commercial markets of UAE. Corrugated sheet manufacturers in UAE support the growing construction industry by providing durable, cost-effective materials for roofing and cladding applications.

Industrial and Warehouse Growth

Increased industrial and warehouse construction has resulted in the increased demand for corrugated metal sheets in those structures due to the hub of global trade in UAE. Corrugated sheets are very commonly used for industrial sheds, warehouses, and cold storage because it's robust enough to bear loads, corrosion resistant, and have a very low maintenance requirement; these aspects play a great role in UAE's severe climate.

Rapid growth in the agricultural sector

The growing agricultural sector in UAE is constantly in demand for these sheets mainly due to applications in controlled environments like greenhouses and livestock shelters. Corrugated plastic and metal sheets offer UV protection, insulation, and ventilation to safeguard crops and animals from the scorching weather. Growth in the agricultural structure sector has therefore translated to growth in demand in the market for fiber corrugated sheets.

Rise in the Packaging Industry

All these have concurred to fuel the growth of the corrugated roof sheeting market in UAE: e-commerce growth, export-orientated industry, and local manufacturing activities. The main reason for this increased use is the strong demand for lightweight and durable packaging, which is also capable of withstanding environmental stress-older corrugated containers. The government of UAE is also nudging towards sustainable packaging solutions, thinking about the recyclability of packaging waste and reducing the environmental impact that packaging wastes cause.

Sources for the above content:

https://datahorizzonresearch.com/corrugated-roofing-sheets-market-6573

https://www.6wresearch.com/industry-report/united-arab-emirates-uae-corrugated-board-packaging-market-outlook

Benefits of Corrugated Sheet in UAE

Corrugated sheets have become a favored choice for numerous businesses and individual homeowners. Listed below are the five primary advantages of utilizing corrugated roofing sheets and the reasons why they are a superior choice.

- • Avoids water accumulation: Due to their distinct shape, corrugated roof sheets facilitate water drainage, ensuring your roof remains free of build-up.

- • Long-lasting: A corrugated roof sheet constructed from materials such as steel sheets or aluminium corrugated sheet can endure for many years with minimal upkeep, only requiring a fresh coat of paint now and then.

- • Durable: Not only are these sheets durable, but they are also lightweight which simplifies handling and installation. It also does not add to the overall weight of the building's structure.

- • Lightweight: Capable of enduring any weather conditions, corrugated sheeting offer a protective shield to your buildings and are resistant to rust.

- • Rot-resistant: Corrugated metal sheets are resistant to rot, unlike many other roofing materials. A lot of metal sheets are coated with chemicals to prevent algae growth.

Types of Corrugated Sheets Available in UAE

Corrugated Metal Sheets

Corrugated metal sheets use high-quality steel and a corrugated pattern to offer exceptional durability. This quality makes them perfect for various commercial and agricultural structures like warehouses, barns, and stables. Additionally, they are lighter in weight compared to numerous other roofing options, which makes them a good fit for various residential constructions. These services involve replacing garage roofs, shed roofs, and other similar structures.

These sheets are available in different thicknesses and lengths. This enables you to discover the ideal size for your project, maximizing the area covered while minimizing leftover materials.

Single-wall corrugated Sheets

A form of corrugated cardboard material called a single wall sheet has two flat liner boards and one fluted layer. While the linerboards offer rigidity and strength, the fluted layer cushions and absorbs shock. They can be found in various grades, widths, thicknesses, and flute shapes to accommodate various packing requirements. To suit certain packaging and marketing demands, this can also be modified with printing, labeling, or branding. Single-wall these sheets are frequently used for crafts and do-it-yourself projects in homes, schools, and a variety of other businesses, such as e-commerce, retail, manufacturing, and logistics.

Double Wall Corrugated Sheets

Corrugated cardboard sheets with two walls are perfect for protecting surfaces, encasing larger objects, or protecting edges. can also be applied on a pallet in between coats. To guard against damage during transit, this product is packaged carefully on a pallet. Double-Thick Cardboard & Sheets Double Wall Sheets are comprised of recycled and post-consumer cardboard. Algae- and water-based inks are also used to print them.

Triple Wall Corrugated Sheets

Triple wall sheets are extraordinarily robust and long-lasting because they have three layers of fluting spaced by four-liner boards. Heavy-duty industrial applications, such as export packaging for huge machinery, automotive parts, and other bulky objects needing utmost protection, are the main purpose for these sheets. Because of their extraordinary strength, triple-wall sheets are perfect for heavy-duty, high-load applications. They provide excellent storage and transit protection for bulky or delicate goods.

Plastic Corrugated Sheets

These sheets, composed of high-density polypropylene corrugated sheet or polyethylene, are robust and lightweight. These sheets are frequently utilized in construction for protective layer applications, reusable packaging, and sturdy signs. Plastic sheets are ideal for outdoor use in settings where longevity and durability are crucial because they are reusable, waterproof, and chemically resistant.

PP Corrugated Sheets

PP Corrugated Sheets, also called Polypropylene Corrugated Sheets or Coroplast Sheets, are plastic sheets that are lightweight and durable, featuring a fluted structure. Due to their outstanding properties like resistance to water, chemicals, and impact, these sheets are widely used in a range of industries.

PVC Corrugated Sheets

PVC corrugated sheet is a durable roofing option, offering strong resistance to chemicals, fire, and impact. This sheet is able to withstand harsh chemical environments that would cause other roofing materials to corrode rapidly, making it perfect for use in industrial, agricultural, and construction roofing, siding, and cladding applications. It comes in different transparent and solid colors as well as numerous designs.

Key Applications of Corrugated Sheets in UAE

Architecture and Construction

These sheets offer strong protection from storms and heavy winds; plus, they require minimal upkeep. They are durable and sturdy as well. These reasons are sufficient for the architectural and construction industry to admire them. Corrugated sheets are utilized in constructing a range of roofs for buildings such as sheds, carports, stadiums, railway stations, schools, bus stops, pet enclosures, and mare for this reason. Corrugated sheet manufacturers play a crucial role in architecture and construction by supplying durable, weather-resistant materials for roofing, cladding, and facades.

Packaging

Another sector where we can notice the extensive usage of corrugated materials is the packaging sector. Corrugated materials are required for a variety of packaging applications, from cardboard to packs. These materials are lightweight and provide mild cushioning to goods, making them ideal for safe and secure shipment and transportation. Corrugated materials can be used to package anything from light electronic goods (e.g., TVs or computer displays) to large industrial equipment, depending on their type and thickness. Furthermore, corrugated boxes are affordable, customizable, recyclable, and reused. Eco-friendly packaging options help companies support the nation's sustainable vision while remaining ecologically conscious.

Construction site fencing and barriers

In UAE construction zones, these sheets are applied to the structural fencing and barrier definition of a construction site. They provide security and privacy, challenging conditions weather-wise. Their versatility in installation and strength makes them a practical answer for relatively temporary enclosures in fast-developing urban areas such as Dubai and Abu Dhabi.

Construction Roofing and Cladding

Corrugated sheets are used intensely in UAE for roofing houses, offices, and industries. Indeed, they can hold out against rough desert climates with extreme temperatures, windy storms, and sandstorms, providing a good level of insulation against heat and energy waste.GI corrugated sheets are widely used for roofing and cladding in construction, offering durability, weather resistance, and affordability.

Commercial and Industrial Sheds

These sheets are used to build commercial and industrial sheds that serve quick, strong workshop, factory, or storage unit solutions. Storeroom space constructions are good for workshops, factories, and others because they are resistant to heavy loads, corrosion-free, low in maintenance, and hence perfect for constructing cost-effective, weather-resistant structures in the harsh desert climates of UAE.

Environmental Impact and Sustainability of Corrugated Sheets

Recyclability

One of these sheets' main environmental advantages is its capacity to be recycled. In contrast to numerous other packaging materials, like single-use plastics, PVC corrugated sheets can be recycled several times without experiencing a noticeable deterioration in quality. The sheets can be sorted and processed through the current recycling infrastructure, avoiding the requirement for additional waste management systems. We can reduce the quantity of plastic trash that ends up in landfills and the ocean by encouraging the recycling of these sheets. This will help to protect the environment and reduce pollution.

Reusability and Durability

These sheets are so resilient, that they can be used for an extended period. A producer of these sheets creates sheets that are immune to physical damage, chemicals, and moisture, in contrast to conventional cardboard or paper-based packaging. Their durability makes it possible to use them repeatedly, which reduces the need for replacements. These sheets are perfect for applications that need hygienic conditions, including food packaging, because they are also readily cleaned and disinfected. We can cut down on waste production and increase the longevity of packing materials by using PVC corrugated roofing sheets instead of disposable ones.

Energy Efficiency

Compared to alternative packaging materials, less energy is used to produce GI corrugated sheets. Melting and extruding the plastic resin is the manufacturing process, which uses comparatively less energy than other processes like glass or papermaking. Furthermore, the lightweight sheets produced by the Indian producer of PP corrugated sheets lower the energy needed for transportation. Reduced energy use in production and shipping results in a smaller carbon footprint and less of an adverse effect on the environment overall.

Reduced Carbon Footprint

Throughout their life cycle, These sheets provide a decreased carbon footprint. Lower greenhouse gas emissions are a result of the energy-efficient production process, as was previously indicated. Moreover, because sheets are lightweight, less fuel is used during transportation, which produces less emissions. Furthermore, the durability and recyclability of sheets lessen the requirement for the creation of virgin materials, which frequently entails resource-intensive procedures. We can reduce carbon emissions and save natural resources by employing recycled resin and prolonging the life of polycarbonate corrugated sheets. Corrugated sheets suppliers contribute to reducing carbon footprints by offering eco-friendly, recyclable materials that promote sustainable building practices in construction.

Contribution to a Sustainable Future

These sheets are essential for encouraging a greener future in light of the worldwide movement towards sustainability. Selecting these sheets from suppliers of PP corrugated sheets shows companies and customers that they care about minimizing plastic waste and preserving resources. Utilizing these sheets, which are strong, recyclable, and energy-efficient, contributes to the shift to a circular economy—one in which resources are recycled, reused, and repurposed. Furthermore, sheets' adaptability makes them suitable for a variety of uses outside of packaging, such as in the building, automotive, and signs sectors, which increases their environmental advantages.

Choosing the Right Corrugated Sheets for Your Project

Corrugated sheets are quite common in the siding and roofing industries. Here are some recommendations for choosing the proper sort of sheet for your project.

- • Determine the project's requirements, such as whether it's an industrial or residential project. If it is industrial, what kind of environment does the sheet have to withstand?

- • Check the weather for extremes, such as frequent hailstorms, intense downpours, high humidity, etc.

- • Shortlist the material based on anticipated use and weather. For instance, metal rusts and galvanized steel are not resistant to saline water. As a result, it is not the best option for coastal regions.

- • When choosing the appropriate corrugated sheet for your project, it's crucial to focus on precise details like grade, coating, etc. in addition to material.

- • Obtain sheets from trustworthy corrugated sheet suppliers. Obtaining these sheets is simple. Getting raw materials this way is simple and hassle-free. You can submit a demand along with the standards and requirements you anticipate for quality, get bids from sellers, compare quotes, and then confirm an order by paying for it. The necessary amount of raw material will be delivered right to your door.

Find leading corrugated sheet suppliers in UAE on TradersFind

TradersFind is a reliable platform for those who are looking for corrugated sheet in UAE. You can find different verified corrugated sheet suppliers in UAE. You can get the complete details such as contact details, location, or WhatsApp number.

Through that, you can get in touch with manufacturers across UAE. In short, TradersFind is the best place to easily connect with the top companies across UAE.

Frequently Asked Questions (FAQs)

Q1: What is the purpose of the corrugated sheet?

A1: Corrugated sheets are excellent options for use in construction elements of modern industrial buildings, such as roofs, claddings, and walls, due to their high strength-to-weight ratio, being lighter and more cost-effective than flat isotropic panels of equal strength.

Q2: What is the thickness of a corrugated sheet?

A2: The thickness of the sheet, typically 0.5mm or 0.7mm, impacts both the weight and longevity of the product. Thinner sheets are commonly used in wall cladding, while 0.7mm thickness is advised for roofs.

Q3: What are the benefits of these types of sheets?

A3: Durable and lightweight: These sheets are able to bend easily and are long-lasting. You can rely on them to endure for an extended period while performing at the utmost level. Their low weight allows for easy handling and installation, all while being able to withstand different seasons.

Q4: What materials are used in these sheets?

A4: These sheets are usually manufactured from materials such as galvanized steel, aluminum sheets, or PVC. These materials are recognized for their robustness, longevity, and ability to withstand corrosion, which makes them perfect for a variety of roofing and cladding uses.

Q5: What are the primary applications of these sheets?

A5: These sheets are mainly used in construction for roofing, wall cladding, and fencing. Their lightweight but strong composition makes them popular in residential and commercial projects.

Q6: What advantages do these sheets offer?

A6: Some advantages are their strongness, light weight, ability to resist corrosion, and capacity to endure severe weather. They are also simple to set up and keep up, which makes them a budget-friendly choice for different construction needs.