29 Jun 2024

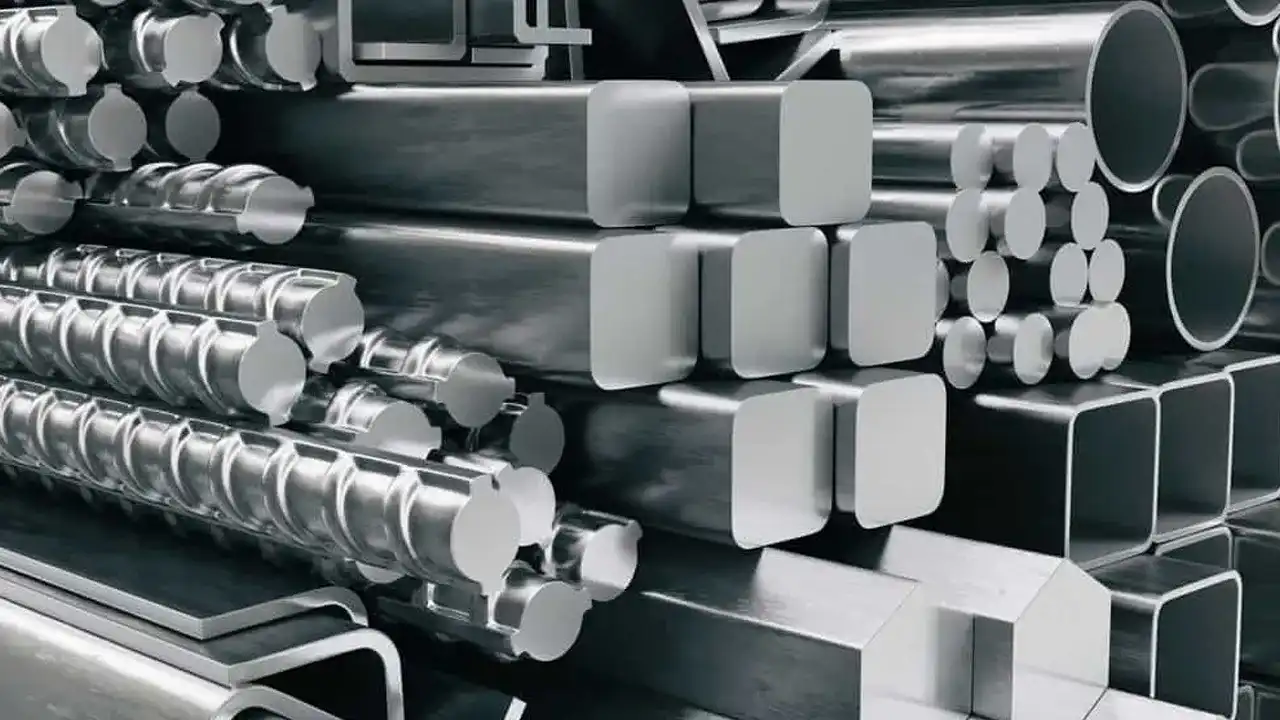

Industrial steel is a versatile metal that comes in several types, each with unique properties that suit different needs. From skyscrapers to kitchen utensils, steel is everywhere in our daily lives. Its strength, durability, and adaptability make it invaluable across industries. Understanding the various types of steel, their properties, and applications is crucial for engineers, builders, and manufacturers. Carbon, alloy, and stainless steels each offer distinct advantages, while their limitations guide their use in specific contexts. The manufacturing processes behind steel production further influence its characteristics. By exploring these aspects, we gain insight into the metal that shapes our world. Industrial steel is a crucial material in various sectors, with different types suited for specific applications. In the UAE, suppliers offer a range of options to meet diverse needs. Let's explore the main types along with their advantages and limitations. This common steel contains iron and carbon. It's affordable and strong, making it great for general use. You can easily shape and weld it, but it tends to rust and doesn't handle extreme heat well. It's widely used in construction and manufacturing due to its versatility and cost-effectiveness. With added chromium, this steel resists corrosion by forming a protective layer. It's durable, easy to clean, and ideal for food processing and medical equipment. While more expensive than carbon steel, its resistance to rust and staining makes it valuable in many industries. Welding can be challenging. Designed for toolmaking, this steel is extremely hard and wear-resistant. It keeps its shape and sharpness under high stress, perfect for cutting tools and dies. However, it's brittle and tough to machine. Special heat treatments are needed to achieve its desirable properties. This steel combines iron with elements like nickel or chromium. It's stronger and more corrosion-resistant than carbon steel, with customizable properties. While pricier, it offers improved performance in demanding conditions. Some types may require special welding techniques for best results. Exposed to the elements, this steel forms a protective rusty layer. It reduces maintenance costs and offers an attractive rusty look, popular in outdoor sculptures and some buildings. However, it's not suitable for constantly wet environments, and its appearance changes over time. HSLA steel is stronger and more durable than carbon steel, yet remains lightweight. It welds well and is used in vehicles and construction. While more expensive than carbon steel, its strength-to-weight ratio makes it valuable. It may be slightly less ductile than regular carbon steel. Understanding the key properties is essential for selecting the right material for specific applications. Industrial steel suppliers in UAE offer products with various properties to meet diverse industry needs. Let's explore their crucial characteristics. Strength is a fundamental property of industrial steel, referring to its ability to withstand applied forces without failure. High-quality steel exhibits excellent tensile, compressive, and yield strength, making it suitable for load-bearing applications in construction and manufacturing. Durability is the steel's ability to maintain its properties and performance over time. Industrial steel manufacturers focus on producing durable materials that can withstand wear, fatigue, and environmental stresses, ensuring long-term reliability in various applications. Corrosion resistance is crucial for industrial steel used in harsh environments. Stainless steel, in particular, offers excellent corrosion resistance due to its chromium content. Industrial steel suppliers in UAE provide corrosion-resistant options for marine, chemical, and outdoor applications. Ductility is the steel's ability to deform plastically without fracturing. This property is important for industrial steel sheets and other products that require forming or shaping. Ductile steel is easier to work with and less prone to brittle failure. Hardness measures the steel's resistance to indentation and wear. Industrial steel manufacturing companies produce materials with varying hardness levels to suit different applications, from soft, easily machined steels to hard, wear-resistant tool steels. Toughness is the steel's ability to absorb energy before fracturing. This type of steel comes with high toughness which makes it desirable in applications where impact resistance is crucial, such as in automotive parts or industrial machinery. The thermal properties, including thermal conductivity and expansion, are important in applications involving heat. Industrial steel companies offer materials with specific thermal properties for use in heat exchangers, boilers, and other temperature-sensitive equipment. Industrial steel is a versatile material used across numerous sectors. In the UAE, industrial steel suppliers cater to diverse industries, providing high-quality materials for various applications. Let's explore some common uses in different fields. The construction sector heavily relies on industrial steel for structural components. Steel beams, columns, and reinforcing bars form the skeleton of many buildings and bridges. Industrial steel manufacturers in UAE produce materials that meet strict building codes and standards. Automotive manufacturers use these steels extensively in vehicle production. From chassis and body panels to engine components, high quality industrial steel provides the strength and durability required in modern vehicles. Steel's ability to absorb impact energy enhances vehicle safety. The energy sector uses industrial steel in various applications. Oil and gas pipelines, offshore platforms, and wind turbine towers all rely on steel's strength and corrosion resistance. Industrial steel suppliers in UAE offer specialized grades for these demanding environments. Industrial steel is crucial in manufacturing equipment and machinery. Machine tools, conveyor systems, and industrial robots often incorporate steel components. They are used for equipment housings and structural elements in factories and plants. The aerospace industry requires high-performance materials, and industrial steel plays a significant role. Aircraft landing gear, engine components, and structural elements often use specialized steel alloys. Industrial steel manufacturing companies produce ultra-high-strength steels for these applications. Ships, offshore structures, and port facilities rely on corrosion-resistant steel. Stainless steel is particularly important in marine environments. Industrial steel companies provide materials that can withstand the harsh conditions of saltwater exposure. Many everyday products contain steel components. Appliances, furniture, and electronic device housings often incorporate steel for its strength, durability, and aesthetic appeal. Industrial steel suppliers offer a range of finishes and grades for consumer product applications, ensuring that steel products meet the diverse needs of manufacturers and end-users alike. The production of industrial steel involves several complex processes. Manufacturing companies in UAE employ various techniques to create high-quality products. Let's explore the key steps in steel manufacturing, from raw materials to finished products. The process begins with the preparation of raw materials, primarily iron ore, coal, and limestone. These materials are carefully selected and processed to ensure the quality of the final steel product. Iron ore is reduced to molten iron in blast furnaces. This process involves heating the ore with coke and limestone at high temperatures, resulting in liquid iron that forms the basis for steel production. The molten iron is converted to steel in basic oxygen furnaces or electric arc furnaces. Alloying elements are added to achieve the desired composition. This stage is crucial for determining the steel's properties. The liquid steel is cast into various shapes, such as slabs, blooms, or billets. Continuous casting is a common method used by industrial steel manufacturers to produce semi-finished products efficiently. The cast steel undergoes primary forming processes like hot rolling or forging. These processes shape the steel and improve its mechanical properties. Industrial steel sheets are often produced through hot rolling. Heat treatment processes such as annealing, quenching, and tempering are applied to enhance the steel's properties. These treatments can significantly affect the strength, hardness, and ductility of the final product. Finally, the steel undergoes secondary processing steps like cold rolling, surface treatments, or machining. These processes give the steel its final form and properties, ready for use in various industrial applications. Industrial steel in UAE is an essential material in our modern world. From construction and automotive to aerospace and consumer goods, it plays a crucial role in various industries. The different types of steel, including carbon, stainless, and alloy steels, offer unique properties to suit specific needs. Key characteristics like strength, durability, and corrosion resistance make steel invaluable in countless applications. The manufacturing process, involving steps from raw material preparation to secondary processing, ensures high-quality products. As we've seen, suppliers in UAE and worldwide provide a wide range of options to meet diverse industry requirements. Understanding steel's types, properties, and applications is crucial for engineers, manufacturers, and builders shaping our world.Types of Industrial Steel

Carbon Steel:

Stainless Steel:

Tool Steel:

Alloy Steel:

Weathering Steel:

High-Strength Low-Alloy (HSLA) Steel:

Key Properties of Industrial Steel

Strength

Durability

Corrosion Resistance

Ductility

Hardness

Toughness

Thermal Properties

Common Applications in Various Industries

Construction Industry

Automotive Sector

Energy Industry

Manufacturing and Machinery

Aerospace Industry

Marine Applications

Consumer Goods

Manufacturing Processes Overview

Raw Material Preparation

Iron Making

Steel Making

Casting

Primary Forming

Heat Treatment

Secondary Processing

Conclusion